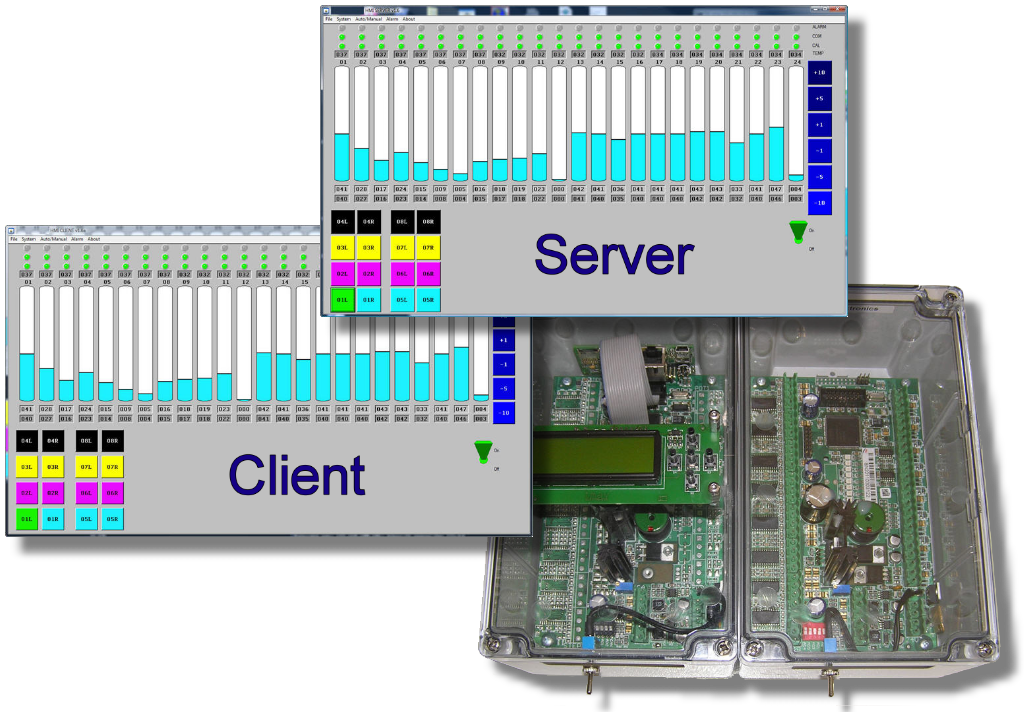

Our company has the experience needed to offered customized automation solutions for printing houses. We have already successfully installed management and control systems to check the volume of ink supplied to printing machines. The installation involves six four-color printing machines. All in all, the system controls 1152 stepper motors via SCADA [Supervisory Control And Data Acquisition] software developed by our company.

Automation characteristics:

- Modular approach

- Independent control board for each machine

- Control board communication via SCADA over Ethernet

- Control board communication with 24 peripheral cards (8 stepper motors/card) over CAN bus

- Automatic valve calibration

- Independent temperature control for each board and overheating protection system

- Communication/Operation status indicators on each board

- Concurrent/Parallel SCADA command execution

- Valve position control via position feedback

- Multiple SCADA clients for parallel control from multiple control stations (HMI touchscreen PCs)

- Control via operation control panel

- Standby function for reduced energy consumption

- Save-and-restore operation to recover valve settings and positions from externally saved files

- Log file

- FW update via Ethernet, USB, or CAN